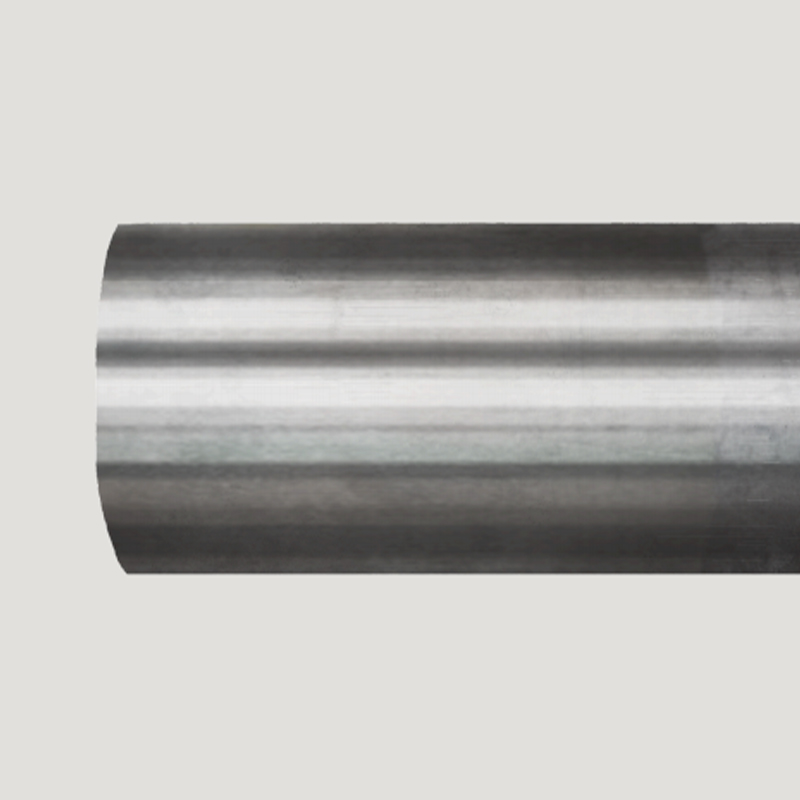

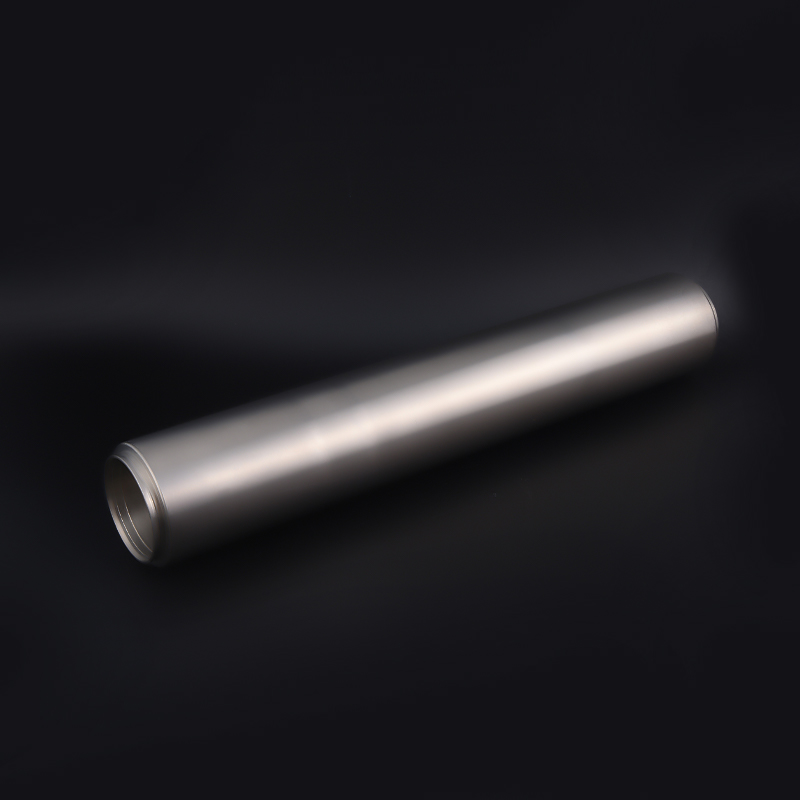

Tantalum ingots are dense, cast ingots of high-purity tantalum (Ta) metal formed through melting (such as electron beam melting or vacuum arc melting). They have a gray-black metallic luster. They serve as a base raw material for subsequent processing into sheet, bar, wire, tube, and powder metallurgy products, and are widely used in demanding high-tech applications.

Key Parameters and Features:

1. Purity: 99.99% (4N). This ultra-high purity ensures excellent chemical stability, corrosion resistance, and good electrical properties, which are key requirements for high-end applications.

2. Dimensions & Weight:

Maximum Dimensions: Customizable. We can flexibly provide ingots of varying lengths, widths, and heights based on the processing capabilities of our customers' equipment and end product requirements.

Maximum Weight: Customizable. The weight of a single ingot can be optimized based on the capabilities of our melting equipment and the customer's production processes.

3. Packaging:

Inner Protection: Each tantalum ingot is tightly wrapped with a special protective film to effectively prevent surface scratches and contamination during transportation and storage.

Cushioning: High-quality pearl cotton is padded between the ingots and between the ingots and the outer box. This material provides excellent cushioning and shock absorption, effectively resisting impact and vibration.

Outer Protection: Packaged in sturdy export-standard wooden crates. The sturdy wooden crates meet the requirements of long-distance sea and land transportation, ensuring the safe arrival of goods at their destination.

4. Primary Application Industries:

Superalloys: As a key alloying element additive, it significantly improves the strength, creep resistance, and high-temperature oxidation/corrosion performance of nickel-based and cobalt-based superalloys.

Aerospace: Used in the manufacture of high-temperature engine components (such as combustion chamber liners and turbine blades), rocket nozzles, and heat-resistant structural parts, meeting the requirements of extreme temperatures, high pressures, and corrosion resistance. Steam Turbines: Used to manufacture high-performance turbine blades and corrosion-resistant components to withstand high-temperature and high-pressure steam environments, extending equipment life and improving efficiency.

English

English