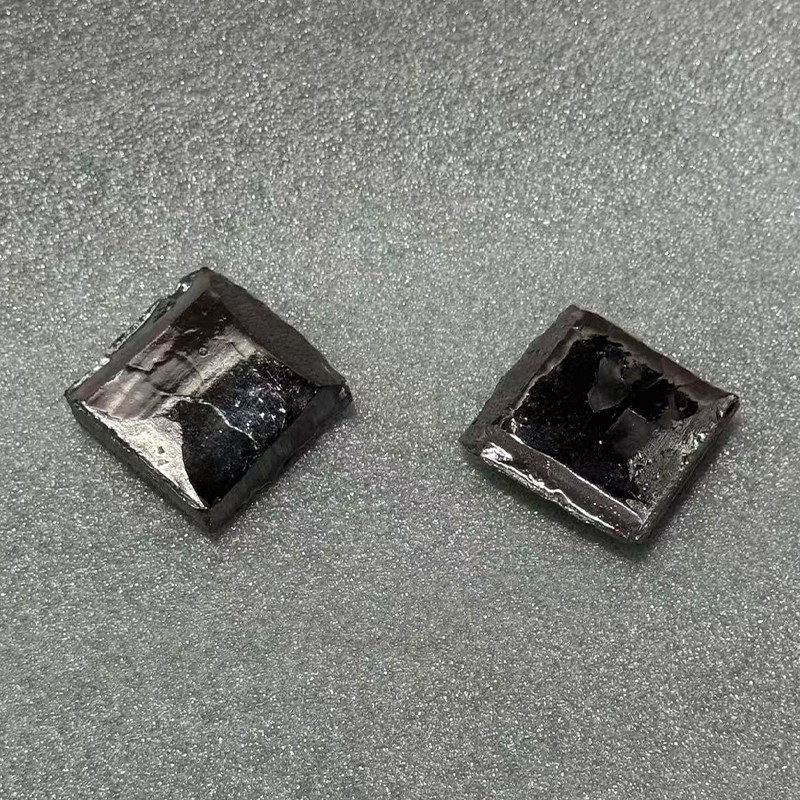

Smelted tantalum is a high-purity tantalum metal purified and produced through high-temperature melting processes such as electron beam melting (EBM) or vacuum arc melting (VAR). This process effectively removes impurities, ensuring the material possesses tantalum's inherent superior properties, such as an extremely high melting point, excellent corrosion resistance, and good biocompatibility. It is a key building block for high-end industrial applications.

▸Purity: 99.998% (4N8). This ultra-high purity is achieved through advanced melting processes such as electron beam melting (EBM) or vacuum arc melting (VAR), minimizing the presence of impurities such as oxygen, nitrogen, carbon, and iron, ensuring the material possesses excellent chemical stability, electrical properties, and mechanical properties.

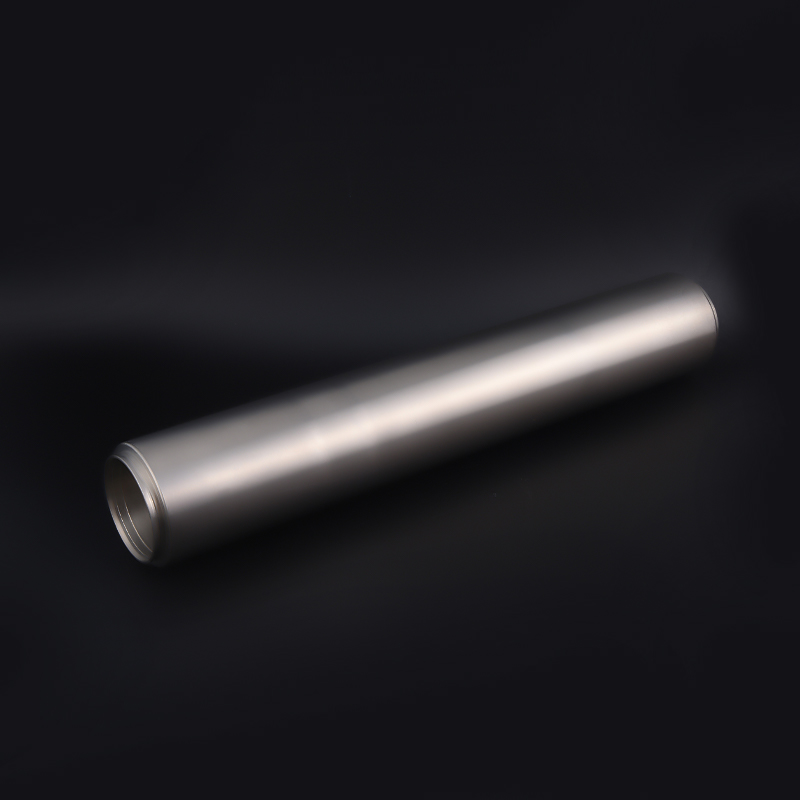

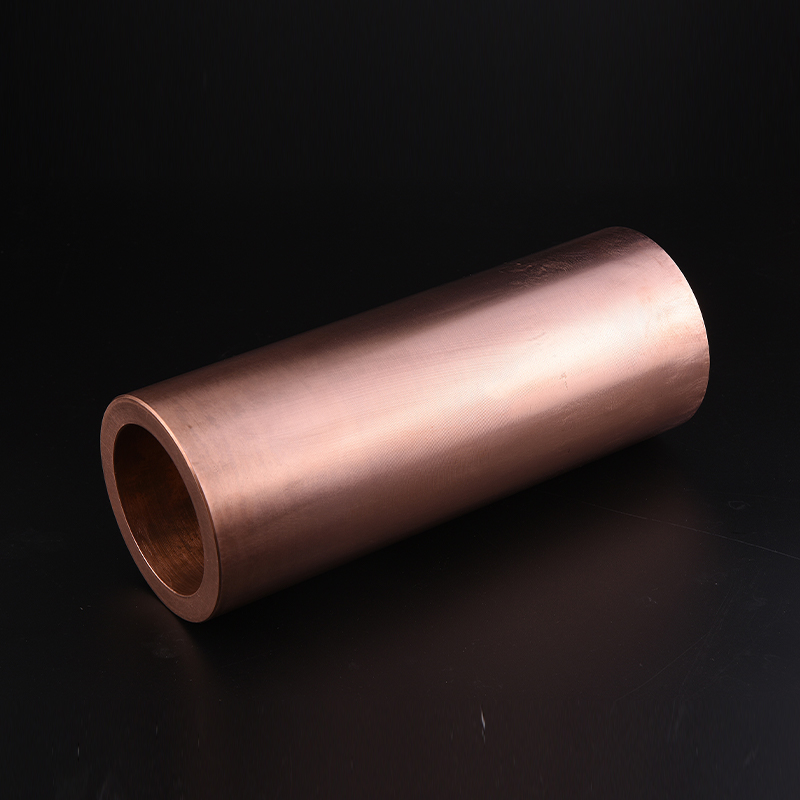

▸Specifications: Customizable maximum dimensions and weights are available. Smelted tantalum ingots can be flexibly provided in various shapes (e.g., ingots, bars, slabs) and sizes to meet customer-specific application requirements, enabling subsequent processing (forging, rolling, cutting).|

▸Packaging: Industrial-grade neutral protective packaging is used. After cleaning and drying, the product is tightly sealed in a plastic bag to prevent moisture and oxidation. The interior is filled with cushioning foam to prevent mechanical damage during transportation, and the outer packaging is sturdy cardboard to ensure the product remains intact during storage and transportation.

▸Applications: Targeted at extreme operating conditions and cutting-edge fields. Main applications:

1. Superalloys: As a key alloying element (such as tantalum-based superalloys), it significantly improves the high-temperature strength, creep resistance, and oxidation resistance of nickel- and cobalt-based superalloys. It is used in the manufacture of hot-end components (turbine blades and guide vanes) of aircraft engines and core components of industrial gas turbines.

2. Steam Turbines: Used in the manufacture of critical components operating in high-temperature, high-pressure steam environments. Its excellent high-temperature strength, corrosion resistance, and erosion resistance extend equipment life and improve operational efficiency and reliability.

3. Aerospace & Aviation: Used in rocket engine nozzle liners, high-temperature spacecraft structures, and ultra-high vacuum system components, meeting the requirements of extreme temperatures, severe corrosion, and high reliability.

English

English