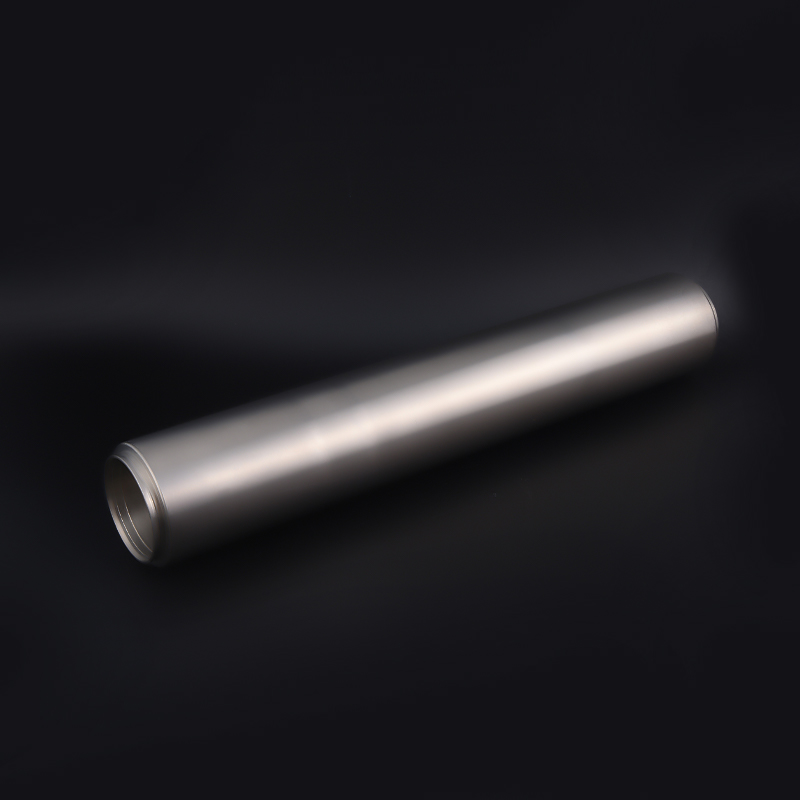

The product boasts high purity and extremely low impurity content, meeting the highest purity requirements for applications. It also boasts strong corrosion resistance, ensuring stable operation in harsh chemical environments. Its excellent mechanical properties enable it to withstand significant stress and deformation.

In production, we utilize our independently developed next-generation molten salt electrolytic purification process combined with vacuum electron beam melting to achieve large-scale mass production of 5N (99.999%) grade ultra-high purity titanium. We are one of only four companies internationally capable of industrially producing ultra-high purity titanium. We continuously invest in technological innovation, participating in or leading numerous national research projects to continuously improve product performance and production efficiency.

Our products are widely used in a variety of key sectors: in aerospace, they are used to manufacture aircraft engine components and fuselage structures. Their high strength and low density effectively reduce aircraft weight, improving fuel efficiency and flight performance. In the medical device sector, their excellent biocompatibility allows them to be used in the manufacture of artificial joints and dental implants. In chemical equipment, their excellent corrosion resistance allows them to be used in the manufacture of reactors and pipelines. In the electronics and information technology sector, they are used as semiconductor sputtering targets in chip manufacturing, helping to improve the performance of integrated circuits.

From raw material procurement to product delivery, we have established a strict quality control system to ensure that every step meets high standards. We can also customize dimensions and weights according to customer needs, providing a full-chain service from raw materials to finished parts. Our professional team provides comprehensive support for customers from product design and manufacturing to after-sales maintenance.

English

English