Nickel Metal: Comprehensive Guide to Applications, Properties, and Benefits

Nickel (Ni) is a silvery-white transition metal known for its strength, corrosion resistance, and versatility. As one of the most widely used metals in industrial applications, nickel plays a crucial role in various sectors, including manufacturing, energy, and technology. Understanding its properties and applications is essential for manufacturers, engineers, and investors seeking to leverage its benefits in their projects.

Key Physical and Chemical Properties of Nickel Metal

Nickel has an atomic number of 28 and an atomic weight of 58.71. Its electron configuration is [Ar] 3d⁸ 4s², placing it in the transition metals category. This configuration contributes to its unique properties, such as high melting and boiling points, making it suitable for high-temperature applications. Nickel exhibits ferromagnetism, meaning it can be magnetized and retains magnetic properties. This makes it valuable in electronic devices and magnetic applications. Additionally, nickel has a high melting point of 1455°C and a boiling point of 2730°C, allowing it to withstand extreme temperatures without degrading. One of nickel's standout features is its exceptional resistance to corrosion. It naturally forms a protective oxide layer on its surface, shielding it from oxidation and chemical attacks. This property is particularly beneficial in harsh environments, such as marine or chemical processing settings. Compared to other transition metals like iron, cobalt, and copper, nickel offers superior corrosion resistance and strength. While iron is prone to rusting and cobalt can be brittle, nickel maintains its integrity under challenging conditions, making it a preferred choice in demanding applications.

Industrial Applications of Nickel Metal

Nickel is essential in modern industries. It strengthens stainless steel, improves durability in nickel alloys, and adds protection and shine through electroplating.

Stainless Steel Manufacturing

Approximately two-thirds of global nickel production is used in stainless steel production. Nickel enhances the steel's strength, ductility, and resistance to corrosion, making it ideal for applications in construction, medical instruments, and kitchen equipment.

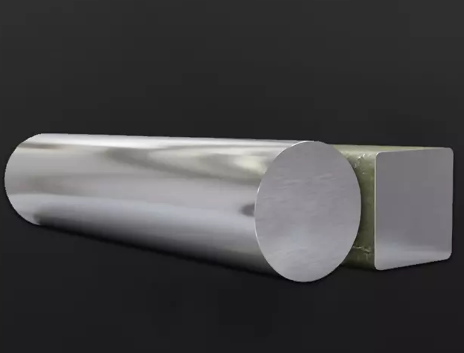

Nickel-Based Alloys

Nickel alloys are integral in industries requiring materials that can withstand high temperatures and corrosive environments. These alloys are used in aerospace components, power generation turbines, and chemical processing equipment, offering durability and reliability in extreme conditions.

Electroplating and Surface Coatings

Nickel is widely used in electroplating to provide a protective and decorative coating on various substrates. This application is common in the automotive industry, electronics, and consumer goods, enhancing both the appearance and longevity of products.

Advantages of Nickel Metal

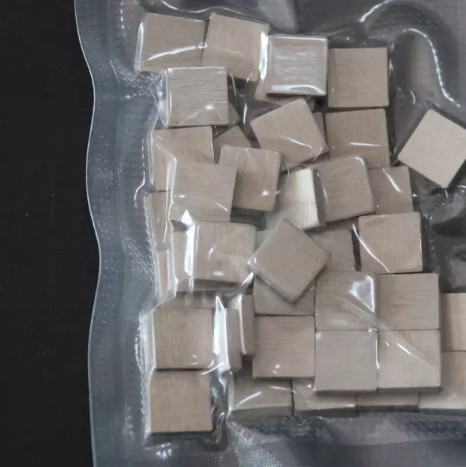

Application1

Application2

Application3

Company Advantage

CRNMC excels in metal purification, full-process production, and technical innovation. Its 5N Nickel Metal offers top corrosion resistance and stability, serving aerospace, semiconductor, and energy industries globally.

Advanced Purification Technology

CRNMC uses leading refining and melting techniques to achieve ultra-high purity metals—up to 99.999% for nickel—ensuring superior material performance and reliability.

Full-Process Manufacturing Capability

The company manages the entire production chain from raw metal refining to finished components, guaranteeing stable quality and faster delivery times.

High-Purity Nickel Metal Excellence

Its 5N-grade Nickel Metal offers exceptional corrosion resistance, thermal stability, and electrical conductivity, ideal for aerospace, semiconductor, and energy industries.

Strong R&D and Global Service Network

With multiple production bases and a professional technical team, CRNMC provides customized solutions and consistent support for clients worldwide.

FAQs

Related Blogs

One Article for You to Read About CRNMC's High Purity Titanium

With the continuous application of titanium products in semiconductor, aerospace, new energy and other industries. End product requirements for upstream raw materials are also becoming more stringent.High purity titanium spongeThe highest national standard for titanium sponge, grade 0A, requires a t

Read MoreNiobium Alloys: Transforming Steel Production And Industrial Applications

Steel has long been one of the most essential materials for modern infrastructure, from towering skyscrapers to bridges and vehicles. However, despite its importance, steel is not always as durable or versatile as industries require. This is where niobium alloys come in.

Read MoreThe Unique Properties of Niobium: Why It's A Critical Material in High-Tech Industries

Niobium, a relatively obscure metal compared to more common materials like aluminum or steel, plays a vital role in modern high-tech industries.

Read MoreCorrosion Resistance of Titanium Metal: What Makes It So Durable?

Titanium is often described as a “wonder metal” for good reason. It’s as strong as steel but nearly half the weight, making it ideal for aerospace and engineering applications.

Read More

Get Touch With Us

If you have any questions or requirements regarding solutions, please feel free to contact our customer service team.

+86-574-6206 7577 8777

tiefeng.zhang@crnmc.com