- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

-300 m, -100-300 m, -100-200 m, etc.

Vacuum packaging

Aerospace, Aviation, 3D Printing, LCD

| Availability: | |

|---|---|

| Quantity: | |

Project | 3N Titanium Powder |

Fe | <300 |

Ni | <100 |

Al | <100 |

Si | <100 |

Cl | <400 |

Mg | <100 |

Mn | <100 |

Cr | <100 |

Cu | <50 |

C | <150 |

N | <300 |

O | <1800 |

H | <200 |

Currently, titanium powders are produced by methods such as sodium or magnesium chloride reduction, mechanical crushing, hydrogenation dehydrogenation, electrolysis and atomization.

Among them, hydrogenation dehydrogenation, electrolysis and rotating electrode atomization can produce high quality titanium powder.

Hydrogenation dehydrogenation method has the advantages of simple operation, low cost and other advantages and become the main method of producing titanium powder.

Hydrogenation dehydrogenation (HDH) is a process to prepare titanium powder by using the reversible properties of titanium and hydrogen.

Titanium absorbs hydrogen to form titanium hydride, which produces brittleness, and is mechanically crushed to make hydrogenated titanium powder, which is then dehydrogenated at high temperatures in vacuum conditions to produce titanium powder.

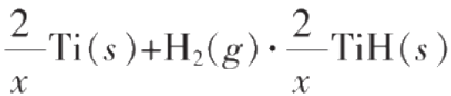

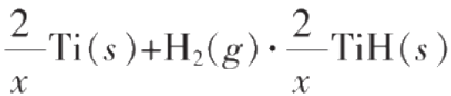

The reaction formula is as follows:

Project | 3N Titanium Powder |

Fe | <300 |

Ni | <100 |

Al | <100 |

Si | <100 |

Cl | <400 |

Mg | <100 |

Mn | <100 |

Cr | <100 |

Cu | <50 |

C | <150 |

N | <300 |

O | <1800 |

H | <200 |

Currently, titanium powders are produced by methods such as sodium or magnesium chloride reduction, mechanical crushing, hydrogenation dehydrogenation, electrolysis and atomization.

Among them, hydrogenation dehydrogenation, electrolysis and rotating electrode atomization can produce high quality titanium powder.

Hydrogenation dehydrogenation method has the advantages of simple operation, low cost and other advantages and become the main method of producing titanium powder.

Hydrogenation dehydrogenation (HDH) is a process to prepare titanium powder by using the reversible properties of titanium and hydrogen.

Titanium absorbs hydrogen to form titanium hydride, which produces brittleness, and is mechanically crushed to make hydrogenated titanium powder, which is then dehydrogenated at high temperatures in vacuum conditions to produce titanium powder.

The reaction formula is as follows:

Copyright © 2023 Ningbo Chuangrun New Materials Co., Ltd. All rights reserved. | Sitemap | Privacy Policy | Support By Leadong