As the titanium oxidation reaction layer is the main factor that affects the physical and chemical properties of titanium castings, it is best to perform a pickling before delivery so that the surface of the castings is clean and bright, which is convenient for judging the appearance quality and level of the castings. Corrosive pickling can be used to adjust the dimensional accuracy of the casting wall thickness. The corrosion rate of the new bath is generally 0.005 to 0.0077mm/min, and the corrosion and cutting ability of titanium castings can be up to 0.2 to 0.4mm. Therefore, during the time-corrosive pickling process, attention must be paid to the problem of hydrogen permeation to avoid hydrogen embrittlement fracture of titanium alloy castings in use. Therefore, the precision titanium alloy castings that have undergone corrosive pickling generally need to be vacuum-annealed later. How to achieve the polishing effect, usually by pickling after sandblasting, the surface reactive layer of titanium can be completely removed.

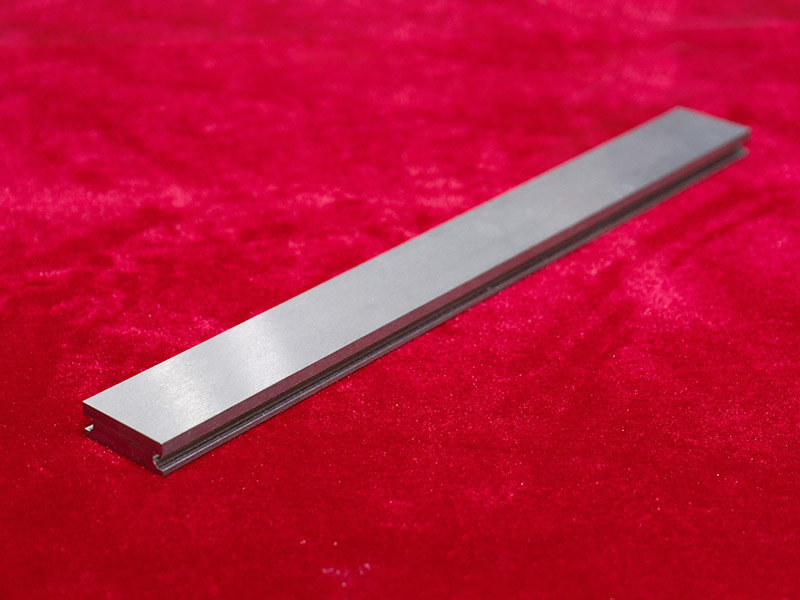

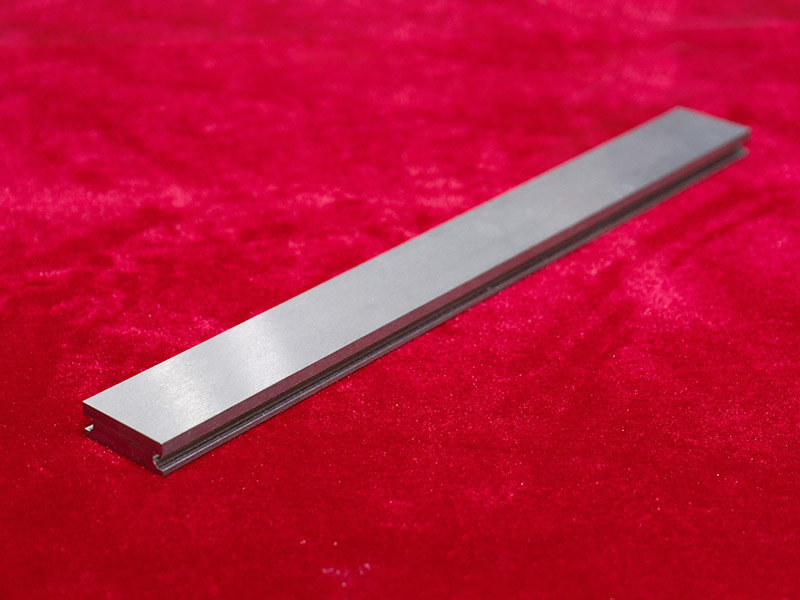

(1) Sandblasting: For the sandblasting of titanium castings, Baigang H rough blasting is usually better, and the blasting pressure is usually controlled below 0.45MPa. When the injection pressure is too high, the sand particles impact the titanium surface and generate intense sparks. An increase in temperature can react with the appearance of titanium. It constitutes secondary pollution and affects the appearance quality. The time is 15-30s, just remove the sintered layer and some oxide layers on the surface of the casting. Other surface reaction layer structures should be quickly removed by chemical pickling. When titanium alloy castings are processed by hot isostatic pressing, the internal pores can be bridged for the first surface pores. And generally it will not affect the dimensional stability of the titanium alloy rod, but the surface pores and the subsurface pores connected to the surface must be removed by grinding, repair welding and polishing. Pores are one of the common defects in titanium rod castings. The size of a single pore is generally no more than 2-3mm, and the small one can reach the micron or sub-micron level that is difficult to see with the naked eye. Pores are one of the sources of cracks in castings. After reducing the fracture and sandblasting of the combined gold castings, the titanium composite castings must be pickled before the surface quality inspection.

(2) Pickling: Pickling can quickly and completely remove the surface reaction layer. The surface will not be polluted by other elements. Both HF-HCI series and HF-HN (J3 series pickling liquids are used for pickling of titanium, but HF-HLl series pickling liquids have a larger hydrogen absorption capacity, while HF-HNO3 series pickling liquids have the least hydrogen absorption, which can be Control the concentration of hno3 to reduce the absorption of S, and can be used to brighten the surface. Usually the concentration of HF is about 3%-5%, and the concentration of HNO is about 15%-30%. Hydrofluoric acid is the main component of the pickling solution. It is one of the few chemical substances that can effectively corrode titanium. The addition of nitric acid to the hydrofluoric acid pickling solution promotes the uniformity and stability of this chemical process. The pickling operation process is; titanium castings placed in a plastic mesh basket , Hoist it with a lifter and immerse it in the pickling tank for pickling. The pickling time is about 3-5 minutes, and the humidity of the pickling tank should be controlled at 20-25°C. After the pickling is completed, the casting must be cleaned in water and then heated Dry in the air stream to maintain a uniform and shiny surface of the castings. In industrial production, plastic rollers can be used instead of net baskets to load the castings and immerse them in the bath towel for pickling. The slow rotation of the ten rollers drives the castings to continue during the pickling process. Stirring prevents the gas generated by the reaction from forming bubbles and adhering to the surface of the casting, so that the pickling process of the casting can be carried out evenly and efficiently.

www.crnmc.com