ABOUT CRNMC

Ningbo Chuangrun New Materials Co., Ltd (CRNMC) was established in June 2012 and has 4 production bases.

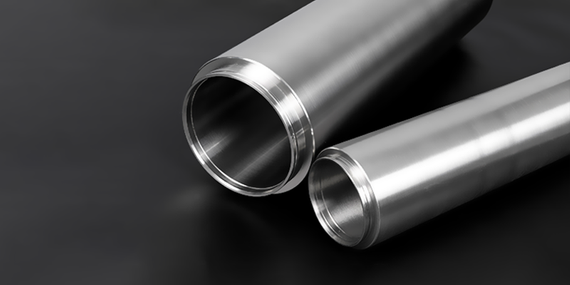

CRNMC is dedicated to material purification, melting, casting and processing of high purity titanium (3N-5N5),copper (6N), nickel (5N),cobalt (5N),niobium(4N) etc.

We provide a full range of electronic grade purity metals such as high purity electrolytic crystal, ingots, forged ingots, powder, plates, etc; and precision parts matching processing for the whole industry.Meanwhile,also produce titanium alloy like TC4,TA15,TiNi,TiAl etc.

In terms of team building,entrepreneurial team of 40 young people with metallurgical backgrounds is dedicated to the industrialization of domestic high-end materials.